Kingpin Rebuilding info

7 Day mobile service rebuilding worn kingpins back to OEM size. We come to you, fully equipped service trucks, fast and friendly service. North Tech Trailer Kingpin Rebuilding is committed to high quality service and customer satisfaction. Our goal is to ensure a perfect finished product at a fair price while working around our customers equipment schedules.

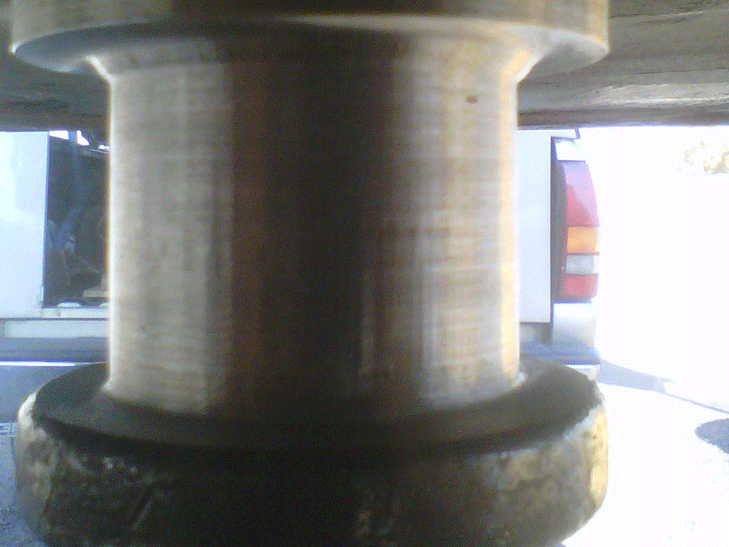

Kingpin Rebuild #1

The gallery above shows the kingpin after rebuild as well as before rebuild

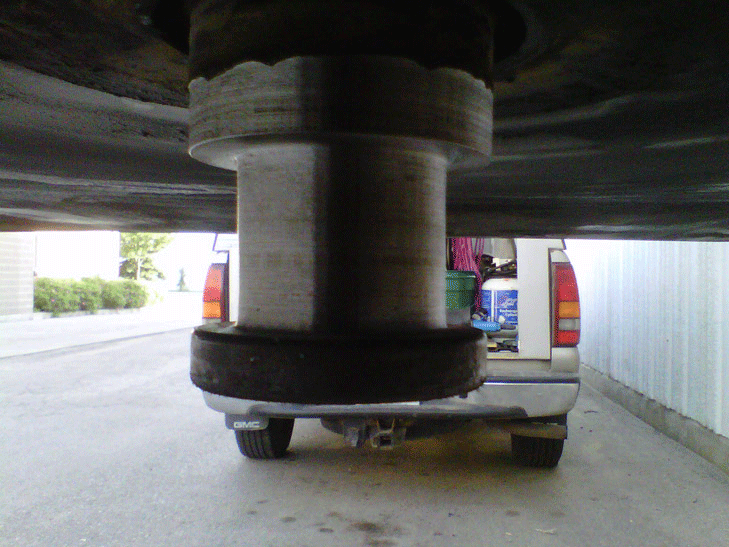

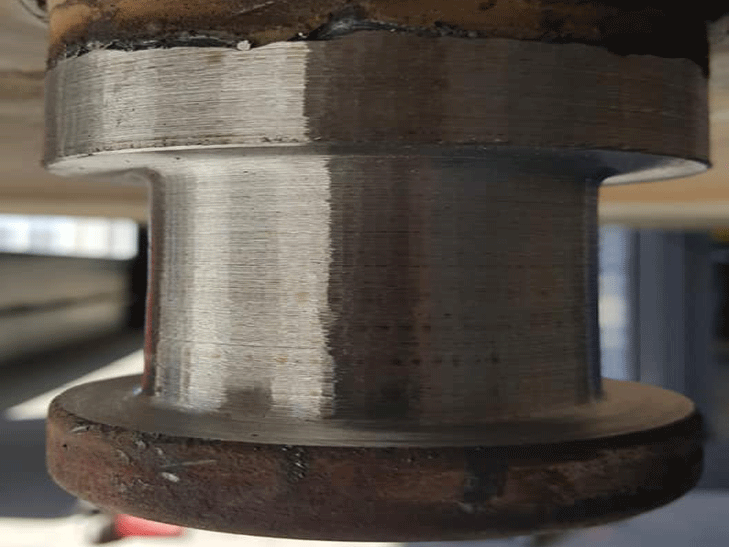

Kingpin Rebuild #2

The gallery above shows the kingpin after rebuild as well as before rebuild

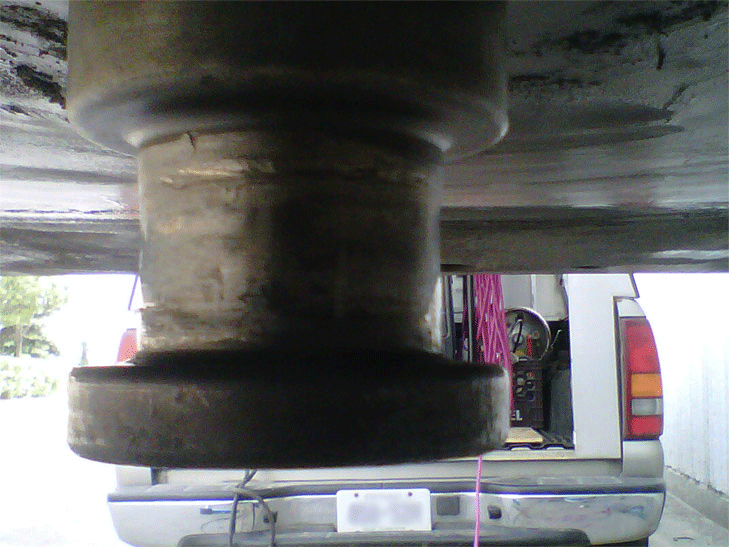

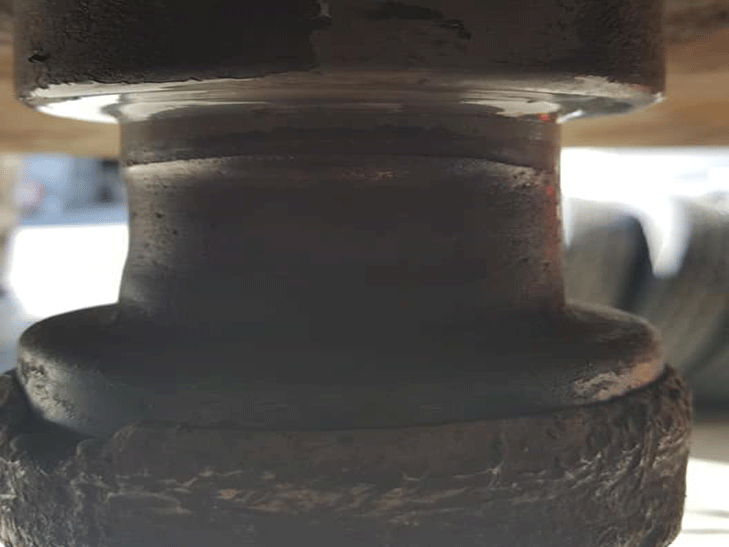

Kingpin Rebuild #3

The gallery above shows the kingpin after rebuild as well as before rebuild

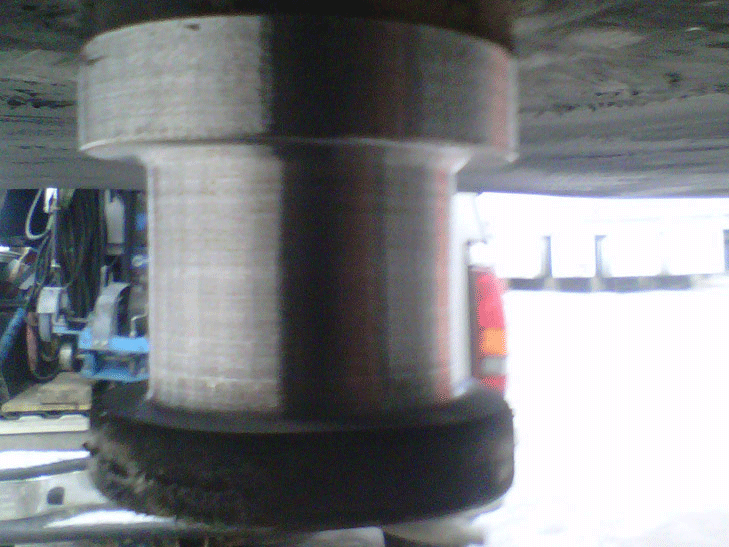

Kingpin Rebuild #4

The gallery above shows the kingpin after rebuild as well as before rebuild

Free

Complimentary Trailer Kingpin wear evaluations and monitoring

Kingpin & Fifth Wheel

Proper fifth wheel lock tester. Full plate and jaw test, not just jaw test for size.

Fifth wheel rebuild stand full rotation to inspect and rebuild fifth wheels.

Locks into comfortable position for rebuilders safety.

Fifth wheel pin puller. Stay clean while getting a good pull force on fifth

wheel handle.

Kingpin test gauge

Proper fifth wheel lock tester. Full plate and jaw test, not just jaw test for size.

Fifth wheel rebuild stand full rotation to inspect and rebuild fifth wheels.

Locks into comfertable position for rebuilders safety.

Fifth wheel pin puller. Stay clean while getting a good pull force on fifth

wheel handle.

Kingpin test gauge

PRICING:

Our pricing starts from $850.00 with approximately 2 hours of downtime.

A standard kingpin replacement typically runs above the $8’000-$10’000 price point, and your trailer may be out of commission 1-2 weeks if a new bolster plate and kingpin are installed.

*One should never weld a new Kingpin into an old bolster plate as old plate cracks may form around the new pin leading to plating failure and trailer separating from the unit.

- Heavy truck, farm equipment, forklift, construction equipment diagnostic testing with our dealer level scan equipment

- 5th wheel rebuilding & replacement

- Truck & Trailer repair

- Welding & Fabricating steel/stainless/aluminum, truck, trailer & equipment repair

- Bolster plate & Kingpin replacement

- Full mobile hydraulic hose crimping & installations for all applications

- Fully equipped service trucks for maintenance & repairs

Kingpin & Fifth Wheel Maintenance Products

Repels water and retains lubricant properties where normal grease water logs and falls off. Resistant to hot and cold.

Prices – Slick & Stick Kingpin Lube

Light lubricant that wont gum up with dirt, prevents fifth wheel locks on Fontaine wheels from holding back and causing premature Kingpin wear or destruction. A must for Kingpin protection! Fifth wheel needs to be washed thoroughly underneath each time applied. Apply Problematic Lock & Lube to all moving parts and slide lock assembly.

Prices – Problematic Lock & Lube

Very smooth, zero resistance lube that has graphite properties to curb bolster plate and fifth wheel plate scaring and wear.

Prices – Black Glass

Trailer Kingpin Rebuilding Process

Our process was developed, tested, and patented in the 1980s and with 40+ years of success, it has been saving thousands of dollars in Kingpin replacement and downtime. The rebuilding process takes approximately 2 hours for proper inspection & rebuilding procedure. After rebuild equipment can immediately return to work. This is done at the customer’s location or any location where the trailer can be dropped and repaired accurately and safely.

Kingpin Rebuild Before & After

Special alloy rod used to rebuild kingpin to OEM size and hardness without compromising kingpin strength. Meets & exceeds all DOT SAE & Welding Bureau Regulations. This process is used across North America for large and small transport companies. We have a lot of references to share and customers we’ve maintained since the beginning.

FREE Complimentary trailer kingpin wear evaluations:

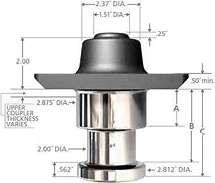

Complimentary Kingpin wear evaluations and monitoring to keep your trailer Kingpins up to safety standards while protecting fifth wheel/bolster plates against damage and premature wear. Our monitoring system checks Kingpin dimensions/abnormal wear characteristics such as upper collar (2.875″) wear compared to the main shaft (2″) wear. Provides you with complete knowledge that when your tractor-trailer is coupled there is no slop and the fifth wheel and kingpin are balanced and mated together with a snug non-binding fit. Our monitoring is achieved with calipers and a thorough inspection of Kingpin, bolster plate, and even fifth wheel effects on the trailer leading to the inspection of the fifth wheel setting and plate condition. The Kingpin gauges that are often used in the shops are not reliable and often indicate pass or fail while not preventing damage and premature wear leading to costly repair

Frequently Asked Questions

Q: How do i know if my kingpin is worn and needs repair?

A: If you run your nail down the kingpin’s backside, you can feel it grooves in from the underside of the upper part of the kingpin. Also, if you move to other trailers that seem tight, but when you are hooked to the trailer in question, it is loose, then it is likely the kingpin needs to be rebuilt. We offer free kingpin inspections in your area and give you the measurements and kingpin/bolster plate evaluation for your decision if you want to do the rebuild.

Q: Does the trailer need to be in a shop to do repair ?

A: No, trailer kingpins can be rebuilt anywhere outside or in, as long as it is on safe and reasonably level gravel or asphalt. Our service trucks are fully equipped to get the job done wherever that may be.

Q: How long will the rebuild take?

A: The rebuilding process from start to finish takes approximately two hours, after which the trailer is immediately ready to return to work.

Q: Is there warranty on the rebuild?

A: Yes, there is a two-year wear warranty; however, our rebuilds typically outlast the trailer life under normal wear conditions, the exceptions being a faulty 5th wheel unit or driver abuse which can lead to early failure.

Q: Does Rebuilding the kingpin weaken it and will it break?

A: All kingpins are carefully inspected and adequately preheated before welding commences; this keeps the materials’ molecular state stable without changing the structure or integrity of the kingpin.

Highlighted Features

Fully Mobile

Fully equipped service trucks for maintenance & repairs

Advanced Diagnositc Tools

Heavy trucks, cars, pickups, farm equipment, forklifts, construction equipment diagnostic testing with our dealer level scan equipment

Mobile Air Conditioning Repair on all applications

Cars, pickups, heavy trucks and all off-road equipment

Mobile hydraulic hose crimping

Full mobile hydraulic hose crimping & installations for all applications